What do you think is the cost of port congestion?

A few hours of delay? A few dissatisfied customers? A few ships waiting to dock?

In terms of costs, it runs in billions of dollars. For instance, the delay of a 40-foot container going from Shanghai to Los Angeles amounted to $6,700 during the global supply chain crisis of 2023.

If the container was going to New York, delays could cost $8000. Considering that we are still feeling the effects of last year, this amount is expected to increase to $10000 in the coming months.

But let’s look at the big picture, beyond the material aspect. Ports in Asia, Europe, and across the world are struggling to deal with port congestion.

This can spark fears of inflation and product shortages. The situation is particularly worrisome around the holiday seasons when the demand for products is high.

It forces retailers to over-order in the hope of managing risks. However, it ends up creating more pressure on supply chain bottlenecks.

AI for Supply Chain Resilience

But all hope isn’t lost.

This in turn enhances decision-making and operational efficiency at the executive level. Let’s look at the key functionalities of AI in greater detail.

AI in Predictive Analytics

By analyzing historical and real-time data, AI can identify patterns and predict bottlenecks, allowing executives to make proactive adjustments. This capability is crucial for maintaining smooth operations and avoiding costly delays.

Real-Time Data Analysis

Real-time data analysis provides instant insights into port activities. AI systems continuously monitor various data points, from vessel movements to cargo handling, ensuring that executives have up-to-date information.

Automated Scheduling

AI-driven automation optimizes port scheduling by considering multiple variables such as vessel arrival times, cargo volume, and workforce availability. Automation reduces human error, increases efficiency, and ensures that resources are allocated effectively.

What are the Benefits of AI in Port Management?

Improved Risk Management

AI’s ability to predict and mitigate risks helps companies avoid disruptions that can have severe financial and operational impacts. By proactively addressing potential issues, businesses can maintain continuity and protect their bottom line.

Cost Efficiency

Automated processes reduce the need for manual intervention, lowering labor costs and minimizing errors. Additionally, AI optimizes resource allocation, ensuring that equipment and personnel are used where they are most needed.

Enhanced Operational Visibility

AI systems provide a comprehensive view of port operations, highlighting areas of improvement and potential bottlenecks. This transparency allows executives to make informed strategic decisions, aligning operations with corporate goals and driving overall performance improvements.

Optimized Resource Allocation

AI helps in the efficient allocation of resources like labor, equipment, and space by predicting demand and usage patterns. This reduces waste and ensures that resources are available when and where they are needed most.

Real-Time Decision-Making

AI can process vast amounts of data in real-time, providing port managers with actionable insights for better decision-making. This can include optimizing vessel docking schedules, managing traffic within the port, and responding to emergencies more effectively.

Data-Driven Insights

AI can analyze historical and current data to identify trends, forecast future demands, and provide strategic insights for long-term planning. This helps in making informed decisions regarding infrastructure development, investment, and policy-making.

Automation of Repetitive Tasks

AI can automate routine tasks such as documentation, customs processing, and inventory management. This reduces the likelihood of human error, speeds up processes, and frees up human resources for more complex tasks.

Is it Easy to Integrate AI with Maritime Operations

AI systems can be embedded into current workflows without major disruptions, providing actionable insights that enhance strategic decisions. In other words, maritime businesses can align their operations with corporate goals more effectively.

For instance, AI can integrate with existing logistics platforms to provide a unified view of the supply chain. This integration enables better coordination between different parts of the operation, from port authorities to shipping companies. The result is a more cohesive and efficient system that supports strategic objectives.

Moreover, AI in transportation allows executives to process and analyze vast amounts of data quickly to ensure they can make timely decisions. This capability is crucial for adapting to changing conditions and maintaining a competitive edge in the maritime industry.

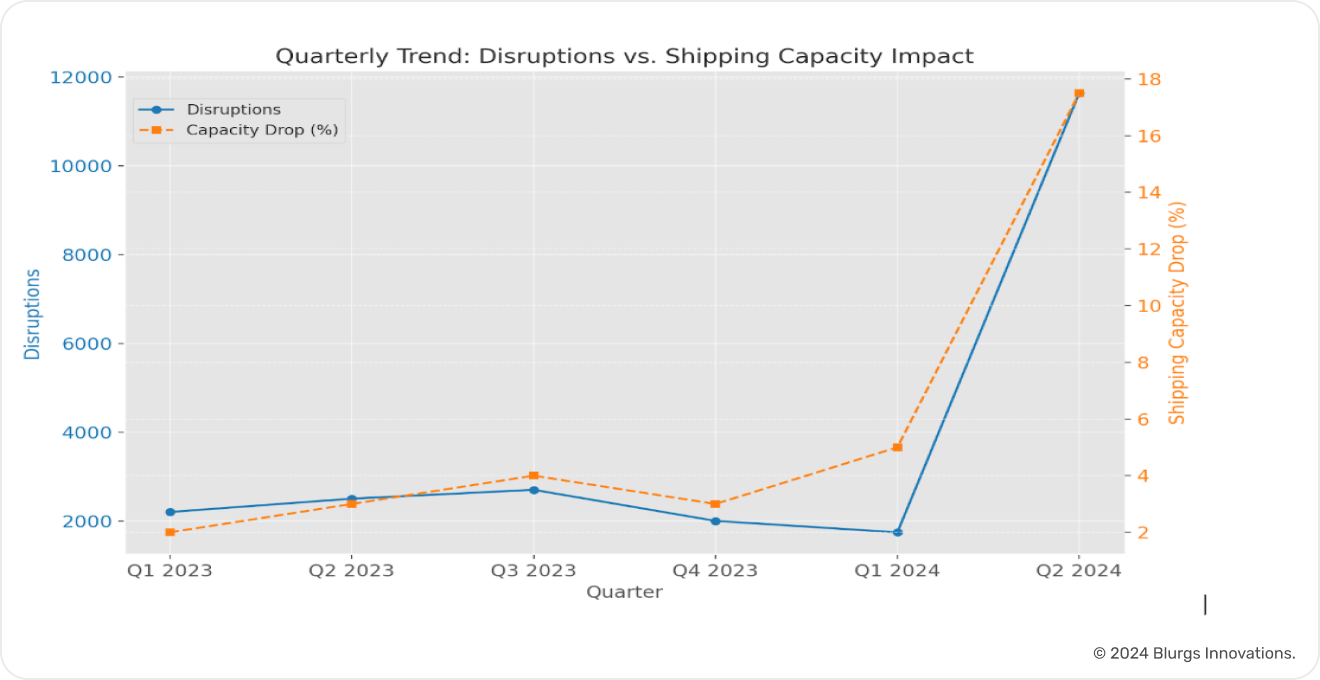

The Global Supply Chain Crisis of Late 2023

What was the Global Supply Chain Crisis?

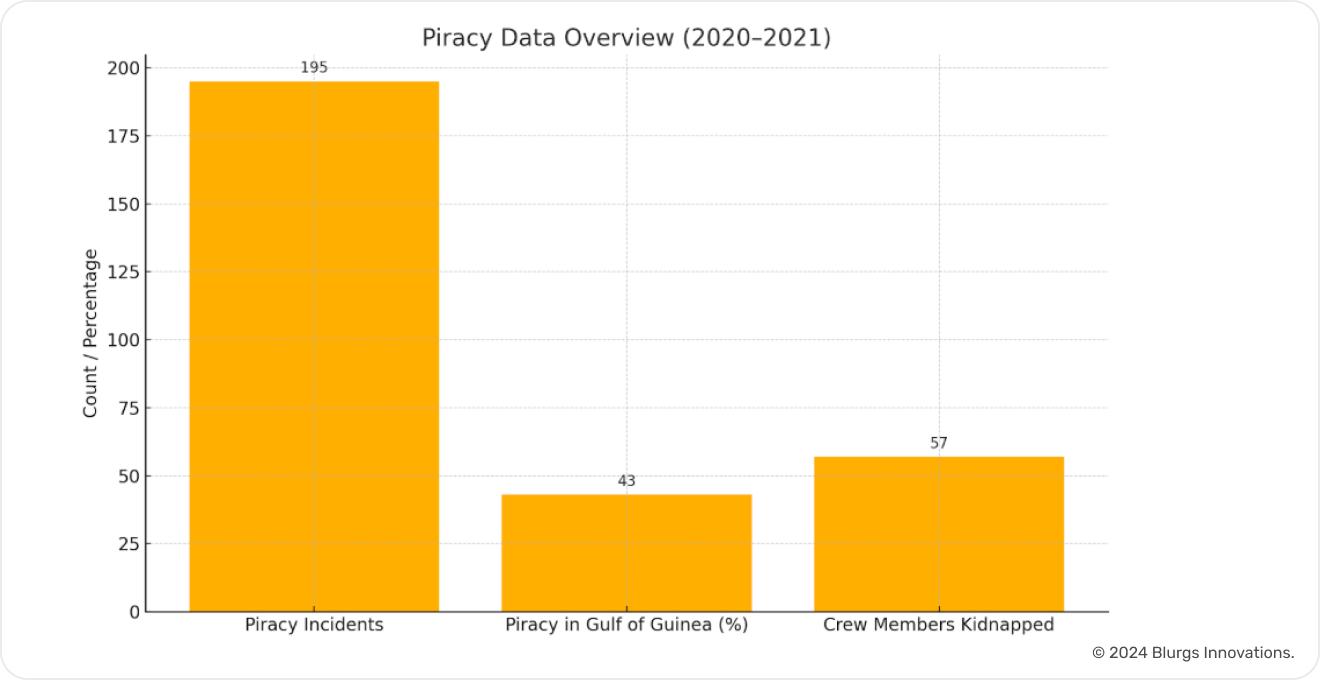

Geopolitical Tensions

The Russia-Ukraine conflict continued to disrupt supply chains, particularly affecting energy and commodity prices. This conflict led to increased fuel costs and restricted access to essential materials, contributing to inflation and higher operational costs across various sectors.

Labor Shortages

A shortage of truck drivers and port workers persisted, further complicating logistics. A survey indicated that 71% of global companies highlighted raw material costs and labor shortages as their top supply chain threats for 2023.

Material Shortages

The semiconductor shortage, which began during the pandemic, remained a critical issue, particularly for the automotive and electronics sectors. This shortage continued affecting production capabilities into 2023.

Increased Demand and Supply Chain Complexity

As consumer demand surged post-pandemic, businesses struggled to keep up due to the complexities of their supply chains. Many companies had adopted lean manufacturing practices, which left them vulnerable to sudden shifts in demand.

Port Congestion and Shipping Delays

While overall port congestion had decreased by 60% compared to previous years, significant delays still occurred, particularly in major U.S. ports. Shipment delays between China and key U.S. and European ports had quadrupled since March 2022, indicating ongoing challenges in logistics.

What was the Economic Impact of the Crisis?

The cumulative cost of the supply chain crisis was estimated to exceed $20 billion in 2023, reflecting the extensive economic ramifications of these disruptions.

Moreover, the Global Supply Chain Pressure Index showed signs of improvement, nearing its lowest level in nearly two years. But many businesses continued to report significant losses and disruptions, highlighting the ongoing fragility of global supply chains

What did We Learn from the Global Supply Chain Crisis?

Record Waiting Times

By late 2023, the average waiting time for container ships at major ports had increased dramatically. At the Port of Los Angeles and Long Beach, for example, ships waited an average of 10-14 days to dock, compared to 2-3 days in pre-crisis periods.

Major global ports, including Shanghai and Rotterdam, reported similar congestion levels.

Increased Vessel Backlogs

In late 2023, the number of container ships waiting offshore reached unprecedented levels. The Port of Los Angeles recorded over 100 ships anchored at sea, a stark contrast to the 40 vessels reported during the same period in 2022.

This backlog delayed deliveries and strained logistics networks, leading to increased operational costs for shipping companies and retailers.

Skyrocketing Shipping Costs

Container shipping rates surged by over 600% in the latter half of 2023, driven by high demand and limited capacity. These soaring costs forced many companies to reconsider their pricing strategies, leading to increased prices for consumers and reduced profit margins for retailers.

Increased Operational Costs

With congestion came increased storage fees. Many ports began charging demurrage fees for containers that remained on-site longer than a specified period. Some companies reported storage fees rising by 200% compared to pre-crisis levels.

The charter market also saw unprecedented rates, with some vessels being chartered for $175,000 per day. This significantly impacted the overall cost structure of shipping operations.

Imbalanced Container Availability

The crisis led to an imbalance in container distribution, with shortages in some regions and surpluses in others. This disparity was exacerbated by shipping lines skipping port stops to avoid congestion, further complicating logistics.

Many retailers faced inventory shortages, particularly in sectors like electronics and consumer goods. Goods remained stuck in congested ports for weeks.

Just-in-Time (JIT) Supply Chain Vulnerability

The JIT inventory model, which relies on minimal stock levels and rapid replenishment, was severely tested. Companies that relied heavily on JIT found themselves unable to meet demand due to delays, leading to stockouts and lost sales.

Could AI have Managed the Crisis Better?

While it cannot prevent all port congestion, AI in logistics handling provides powerful capabilities to enhance visibility, agility, and resilience. Ports that invested in AI solutions were better positioned to navigate the challenges of the 2023 supply chain crisis.

Improved Demand Forecasting

AI-powered predictive analytics could have helped port authorities and shipping lines better forecast demand and optimize capacity.

Machine learning models can analyze historical data, market trends, and external factors to anticipate surges in cargo volumes.

More accurate demand forecasting would have enabled ports to prepare for congestion spikes and allocate resources more effectively.

Automated Port Operations

Robotic process automation and AI in cargo tracking could have streamlined and optimized port workflows, including vessel scheduling, and gate operations. Automated systems using AI could dynamically adjust operations based on real-time data to minimize bottlenecks and delays.

Enhanced Supply Chain Visibility

AI-powered supply chain visibility platforms could provide end-to-end tracking of containers, vessels, and cargo. Integrating data from sensors, GPS, and other sources into a centralized AI system would enable ports to quickly identify and respond to disruptions

Predictive Maintenance

AI could analyze sensor data from port equipment like cranes and vehicles to predict when maintenance is needed. Proactive maintenance guided by AI would minimize breakdowns and keep equipment running at peak efficiency.

Fewer equipment failures would reduce delays and improve reliability of port operations. This could prove vital during a global crisis.

Lead Your Company into the Future with AI

Download our ebook today and understand how to use AI in supply chain management.

Use our insights and stay ahead of the curve, ensuring your business remains a leader in maritime logistics.